F700 Driver

he truly fantastic specifications of the F700 make this VFD from Mitsubishi Electric an absolute must for your drive systems. The F700 inverter is built to optimize 3-phase motor control, saving energy for virtually all general purpose applications.

PRODUCT FEATURES:

-

NEMA 1 UL Type 1 Enclosure Designs: Drive can be mounted as a stand-alone unit.

-

Single Phase Input: UL/cUL listed for use with single phase input supply.

-

Ease of Programming: Taken to higher levels with the new DU07 programming dial and FR-Configurator programming software.

-

Windmill Start: F700 measures residual motor slot ripple to determine both the speed and direction of rotation of a coasting motor and can swiftly and smoothly bring it under control when required - whichever way its spinning.

-

Enhanced Energy Savings: An improved version of Mitsubishi Electrics famous energy-optimization software boosts motor efficiency to unprecedented levels and intelligently maximizes energy savings.

-

Power Dip Ride-Through: Allows the inverter to continue to run during short power supply interruptions - reducing nuisance tripping.

-

Overvoltage Avoidance: The F700 measures DC bus levels when decelerating and controls drive speed to eliminate nuisance tripping.

-

Remote I/O Capability: Drive I/O can be configured over a network to work independently of the drive, reducing cost and making more efficient use of the available network nodes.

-

Independent RS-485 Connections: Allow serial communications and keypad operation at the same time with no options needed. F700 supports Modbus RTU as well as the standard Mitsubishi Electric protocol.

F700 Series The truly fantastic specifications of the F700, make this VFD from Mitsubishi Electric an absolute must for your drive systems.

- NEMA 1 UL Type 1 Enclosure Designs: Drive can be mounted as a stand-alone unit where required. (Plenum rated)

- Ease of Programming: Taken to new levels with the new DU07 programming dial and FR-Configurator programming software

- Built-in EMC filter: Conforms to EN61800-3 2nd environmental

- Energy Savings: Optimum Excitation Control

- The popular setting dial makes operation easy

- Control terminals can be used over a network as remote I/O

- An operation panel can be installed on the front cover and is detachable (Cable connector option is required)

- PU/EXT (operation mode) switchover key is available

- RS-485 communications as standard - Mitsubishi or Modbus RTU protocol

- Windmill start: Catch a reverse spinning load

- Regeneration avoidance

- PID sleep mode

- Pre-soak mode

- 3 user programmable skip frequencies

- Remote I/O capability: All the drive I/O can be read or controlled over a network

- UL Listed for single phase input

F700 Ratings 200-240V Class

Input: 1 Phase/3 Phase - Output Voltage: 3 Phase 200-240V at 60Hz • Voltage Tolerance: 170-264V at 60Hz Available Braking Torque: 15% Torque Continuous |

SLD (40°C) |

LD |

Model Number (*4) |

Frame Size |

Cooling Method |

Protective Rating |

Stocked Item |

110% OL / 1min |

120% OL / 1min |

|

|

|

|

|

120% OL / 3 sec |

150% OL / 3 sec |

|

|

|

|

|

Hp (*1) |

FLA |

Hp (*1) |

FLA |

|

|

|

|

|

1 |

4.6 |

1 |

4.2 |

FR-F720-00046-NA |

A |

Self Cooling |

UL Type 1 - Plenum Rated |

S |

2 |

7.7 |

2 |

7 |

FR-F720-00077-NA |

B |

S |

3 |

10.5 |

3 |

9.6 |

FR-F720-00105-NA |

C |

Forced Air Cooled |

S |

5 |

16.7 |

5 |

15.2 |

FR-F720-00167-NA |

C |

S |

7.5 |

25 |

7.5 |

23 |

FR-F720-00250-NA |

C |

S |

10 |

34 |

10 |

31 |

FR-F720-00340-NA |

D |

S |

15 |

49 |

15 |

45 |

FR-F720-00490-NA |

D |

S |

20 |

63 |

20 |

58 |

FR-F720-00630-NA |

E |

S |

25 |

77 |

25 |

70 |

FR-F720-00770-NA |

F |

S |

30 |

93 |

30 |

85 |

FR-F720-00930-NA |

F |

S |

40 |

125 |

40 |

114 |

FR-F720-01250-NA |

F |

IP00 (*2) |

S |

50/60 |

154 |

50 |

140 |

FR-F720-01540-NA |

G |

S |

60 |

187 |

60 |

170 |

FR-F720-01870-NA |

H |

S |

75 |

233 |

75 |

212 |

FR-F720-02330-NA |

H |

S |

40 |

125 |

40 |

114 |

FR-F720-01250-NAN1 |

F |

NEMA 1 |

- |

50/60 |

154 |

50 |

140 |

FR-F720-01540-NAN1 |

G |

- |

60 |

187 |

60 |

170 |

FR-F720-01870-NAN1 |

H |

- |

75 |

233 |

75 |

212 |

FR-F720-02330-NAN1 |

H |

- |

100/125 |

316 |

100 |

288 |

FR-F720-03160-NA |

K |

IP00 (*2) |

S |

150 |

380 |

125 |

346 |

FR-F720-03800-NA |

K |

S |

200 |

475 |

150 |

432 |

FR-F720-04750-NA |

K |

- |

Input: 1 Phase / 3 Phase • Output Voltage: 3 Phase 380-480V at 50/60Hz• Voltage Tolerance: 323-528V at 50/60Hz • Available Braking Torque: 15% Torque Continuous |

SLD (40°C) |

LD |

Model Number (*4) |

Frame Size |

Cooling Method |

Protective Rating |

Stocked Item |

110% OL / 1min |

120% OL / 1min |

|

|

|

|

|

120% OL / 3 sec |

150% OL / 3 sec |

|

|

|

|

|

Hp (*1) |

FLA |

Hp (*1) |

FLA |

|

|

|

|

|

1 |

2.3 |

1 |

2.1 |

FR-F740-00023-NA |

C |

Self Cooling |

UL Type 1 - Plenum rated |

S |

2 |

3.8 |

2 |

3.5 |

FR-F740-00038-NA |

C |

S |

3 |

5.2 |

3 |

4.8 |

FR-F740-00052-NA |

C |

S |

5 |

8.3 |

5 |

7.6 |

FR-F740-00083-NA |

C |

S |

7.5 |

12.6 |

7.5 |

11.5 |

FR-F740-00126-NA |

C |

S |

10 |

17 |

10 |

16 |

FR-F740-00170-NA |

D |

Forced Air Cooled |

S |

15 |

25 |

15 |

23 |

FR-F740-00250-NA |

D |

S |

20 |

31 |

20 |

29 |

FR-F740-00310-NA |

E |

S |

25 |

38 |

25 |

35 |

FR-F740-00380-NA |

E |

S |

30 |

47 |

30 |

43 |

FR-F740-00470-NA |

F |

S |

40 |

62 |

40 |

57 |

FR-F740-00620-NA |

F |

S |

50/60 |

77 |

50 |

70 |

FR-F740-00770-NA |

G |

IP00 (*3) |

S |

60 |

93 |

60 |

85 |

FR-F740-00930-NA |

H |

S |

75 |

116 |

75 |

106 |

FR-F740-01160-NA |

H |

S |

50/60 |

77 |

50 |

70 |

FR-F740-00770-NAN1 |

G |

NEMA 1 |

- |

60 |

93 |

60 |

85 |

FR-F740-00930-NAN1 |

H |

- |

75 |

116 |

75 |

106 |

FR-F740-01160-NAN1 |

H |

- |

Input: 1 Phase / 3 Phase • Output Voltage: 3 Phase 380-480V at 50/60Hz • Voltage Tolerance: 323-550V at 50/60Hz

Available Braking Torque: 15% Torque Continuous • DC Link Choke is Included With The VFD |

SLD (40°C) |

LD |

Model Number (*4) |

Frame Size |

Fan |

Protective Rating |

Stocked Item |

110% OL / 1min |

120% OL / 1min |

|

|

|

|

|

120% OL / 3 sec |

150% OL / 3 sec |

|

|

|

|

|

Hp (*1) |

FLA |

Hp (*1) |

FLA |

|

|

|

|

|

100/150 |

180 |

100 |

144 |

FR-F740-01800-NA |

H |

Forced Air Cooled |

IP00 (*2) |

S |

150 |

216 |

150 |

180 |

FR-F740-02160-NA |

J |

S |

200 |

260 |

150 |

216 |

FR-F740-02600-NA |

J |

S |

250 |

325 |

200 |

260 |

FR-F740-03250-NA |

K |

S |

300 |

361 |

250 |

325 |

FR-F740-03610-NA |

K |

S |

350 |

432 |

300 |

361 |

FR-F740-04320-NA |

L |

S |

400 |

481 |

350 |

432 |

FR-F740-04810-NA |

L |

S |

450 |

547 |

400 |

481 |

FR-F740-05470-NA |

M |

S |

500 |

610 |

450 |

547 |

FR-F740-06100-NA |

M |

S |

550 |

683 |

500 |

610 |

FR-F740-06830-NA |

M |

S |

650 |

770 |

550 |

683 |

FR-F740-07700-NA |

N |

IP000 (*3) |

S |

700 |

866 |

650 |

770 |

FR-F740-08660-NA |

N |

S |

800 |

962 |

700 |

866 |

FR-F740-09620-NA |

P |

S |

900 |

1094 |

800 |

962 |

FR-F740-10940-NA |

P |

- |

1000 |

1212 |

900 |

1094 |

FR-F740-12120-NA |

P |

- |

Notes:

- Motor ratings shown are intended as guidelines only - based on 4 pole standard induction motors.

- NEMA 1 conduit adapter option required for types 01250 - 04750 200V class product.

- NEMA 1 conduit adapter option required for types 00770 - 06830 400V class product.

For single phase input, derate output current by 40% (Models up to F720-03800-NA, F740-04810-NA.)

F700 General Specifications

Control Specifications |

Control System |

High carrier frequency PWM control (V/F control)/optimum excitation control/simple magnetic flux vector control |

Output Frequency Range |

0.5 to 400Hz |

Frequency Setting Resolution |

Analog Input |

0.015Hz/0 to 60Hz (terminal 2, 4: 0 to 10V/12bit); 0.03Hz/0 to 60Hz (terminal 2, 4: 0 to 5V/11bit, 0 to 20mA/approx. 11bit, terminal 1: -10V to +10V/11bit); 0.06Hz/0 to 60Hz (terminal 1: 0 to ±5V/10bit) |

Digital Input |

0.01Hz |

Frequency Accuracy |

Analog Input |

Within ±0.2% of the max. output frequency (25°C ± 10°C) |

Digital Input |

Within 0.01% of the set output frequency |

Voltage/Frequency Characteristics |

Base frequency can be set from 0 to 400Hz. Constant torque/variable torque pattern or adjustable 5 points V/F can be selected |

Starting Torque |

120% (3Hz) when set to simple magnetic flux vector control and slip compensation |

Acceleration/Deceleration Time Setting |

0 to 3600s (acceleration and deceleration can be set individually), linear or S-pattern acceleration/deceleration mode can be selected. |

DC Injection Brake |

Operation frequency (0 to 120Hz), operation time (0 to 10s), operation voltage (0 to 30%) variable |

Stall Prevention Operation Level |

Operation current level can be set (0 to 150% adjustable), whether to use the function or not can be selected |

Operation Specifications |

Frequency Setting Signal |

Analog Input |

Terminal 2, 4: 0 to 10V, 0 to 5V, 4 to 20mA can be selected. Terminal 1: -10 to +10V, -5 to 5V can be selected. |

Digital Input |

Four-digit BCD or 16-bit binary using the setting dial of the operation panel (when used with the option FR-A7AX) |

Start Signal |

Available individually for forward and reverse rotation. Start signal automatic self-holding input (3-wire input) can be selected. |

Input Signals |

Select any twelve signals using Pr.178 to Pr.189 (input terminal function selection) from among multi-speed selection, second function selection, terminal 4 input selection, JOG operation selection, selection of automatic restart after instantaneous power failure, external thermal relay input, HC connection (inverter operation enable signal), HC connection (instantaneous power failure detection), PU operation/external interlock signal , PID control enable terminal, PU operation, external operation switchover, output stop, start self-holding selection, forward rotation command, reverse rotation command, inverter reset, PTC thermistor input, PID forward reverse operation switchover, PU-NET operation switchover, NET-external operation switchover, command source switchover. |

Operational Functions |

Max. and min. frequency settings, frequency jump operation, external thermal relay input selection, polarity reversible operation, automatic restart after instantaneous power failure operation, continuous operation at an instantaneous power failure, commercial power supply, inverter switchover operation, forward/reverse rotation prevention, operation mode selection, PID control, computer link operation (RS-485). |

Output Signals |

Operating Status |

Select any seven signals using Pr.190 to Pr.196 (output terminal function selection) from among inverter running, up-to-speed, instantaneous power failure/undervoltage, overload warning, output frequency detection, second output frequency detection, electronic thermal relay function pre-alarm, PU operation mode, inverter operation ready, output current detection, zero current detection, PID lower limit, PID upper limit, PID forward rotation reverse rotation output, commercial power supply-inverter switchover MC1, commercial power supply-inverter switchover MC2, commercial power supply-inverter switchover MC3, fan fault output, heatsink overheat pre-alarm, inverter running start command on, deceleration at an instantaneous power failure, PID control activated, during retry, during PID output suspension, life alarm, input MC stop signal, power savings average value update timing, current average monitor, alarm output 2, maintenance timer alarm, remote output, minor failure output, alarm output. Open collector output (5 points), relay output (2 points) and alarm code of the inverter can be output (4 bit) from the open collector. |

When Used With The FR-A7AY (Option) |

Select any seven signals using Pr. 313 to Pr. 319 (extension output terminal function selection) from among control circuit capacitor life, main circuit capacitor life, cooling fan life, inrush current limit circuit life. |

Analog Output |

Select from output frequency, motor current (steady or peak value), output voltage, frequency setting value, running speed, converter output voltage (steady or peak value), electronic thermal relay function load factor, input power, output power, load meter, reference voltage output, motor load factor, energy saving effect, PID set value, PID process value using Pr. 54 “CA terminal function selection (analog current output)” and Pr. 158 “AM terminal function selection (analog output)”. |

Display |

Parameter Unit (FR-DU07/FR-PU04) |

Operating Status |

Output frequency, motor current (steady or peak value), output voltage, alarm indication, frequency setting, running speed, converter output voltage (steady or peak value), electronic thermal load factor, input voltage, output voltage, road meter, cumulative energization time, actual operation time, motor load factor, cumulative energization power, power saving effect, cumulative saving power, PID set point, PID process value, PID deviation value, inverter I/O terminal monitor, input terminal option monitor (*1), output terminal option monitor (*1), option fitting status monitor (*2), terminal assignment status (*2) |

Alarm Definition |

Alarm definition is displayed when the protective function is activated, the output voltage/current/frequency/cumulative energization time right before the protection function was activated and the past 8 alarm definitions are stored. |

Interactive Guidance |

Operation guide/troubleshooting with a help function. (*2) |

Protective/Warning Function |

Overcurrent during acceleration, overcurrent during constant speed, overcurrent during deceleration, overvoltage during acceleration, overvoltage during constant speed, overvoltage during deceleration, inverter protection thermal operation, heatsink overheat, instantaneous power failure occurrence, undervoltage, input phase failure, motor overload, output side earth (ground) fault overcurrent, output phase failure, external thermal relay operation, PTC thermistor operation, option alarm, parameter error, PU disconnection, retry count excess, CPU alarm, power supply short for operation panel, 24VDC power output short, output current detection value over, inrush resistance overheat, communication alarm (inverter), analog input alarm, internal circuit alarm (15V power supply), fan fault, overcurrent stall prevention, overvoltage stall prevention, electronic thermal prealarm, PU stop, maintenance timer alarm (*1), parameter write error, copy operation error, operation panel lock. |

Environment |

Ambient Temperature |

-10°C to +50°C (non-freezing) |

Ambient Humidity |

90% RH or less (non-condensing) |

Storage Temperature (*3) |

-20°C to +65°C |

Atmosphere |

Indoors (without corrosive gas, flammable gas, oil mist, dust and dirt, etc.) |

Altitude, Vibration |

Maximum 1000m above sea level, 5.9m/s2 or less (conforms to JIS C 0040) |

Notes:

- Can be displayed only on the operation panel (FR-DU07).

- Can be displayed only on the parameter unit (FR-PU04/FR-PU07).

- Temperature applicable for a short period in transit, etc.

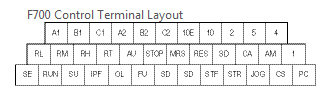

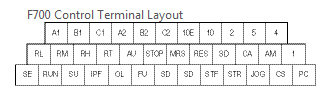

F700 Series Terminal Connection Diagram

|